Big Bag Discharging

Product Description

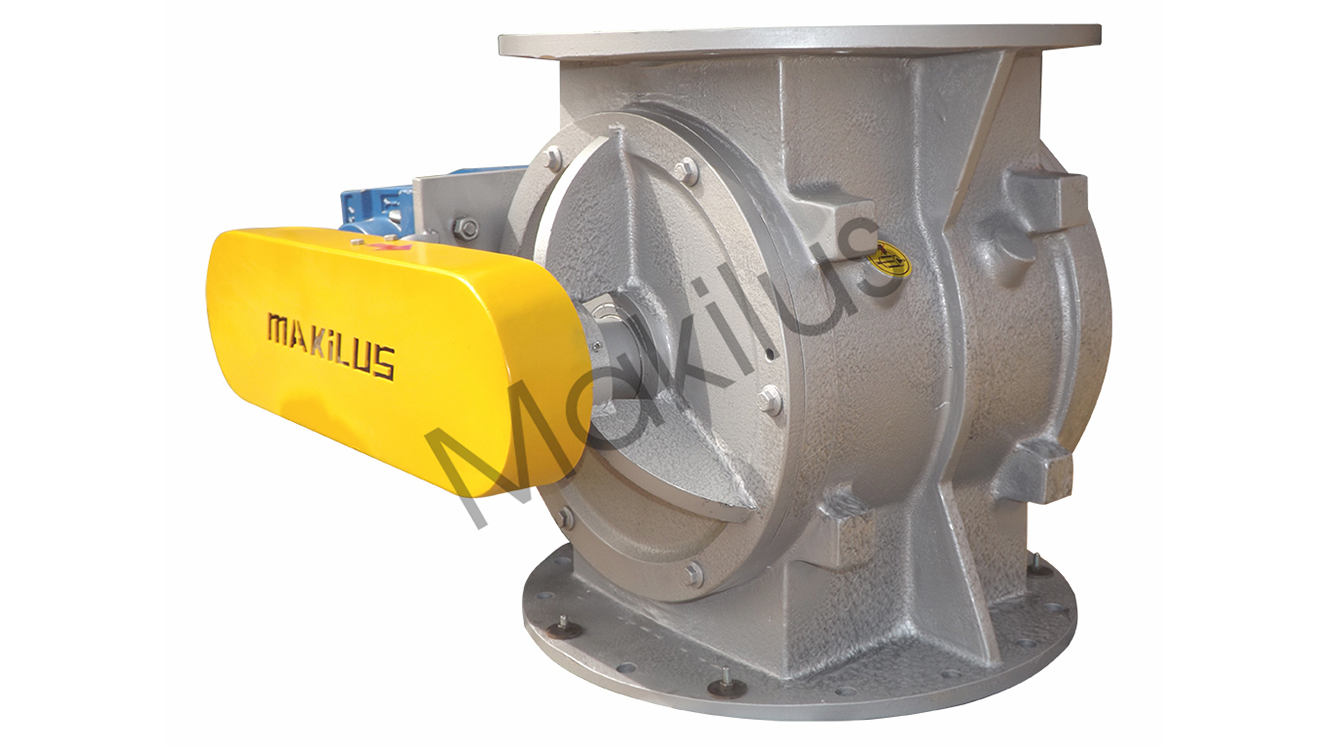

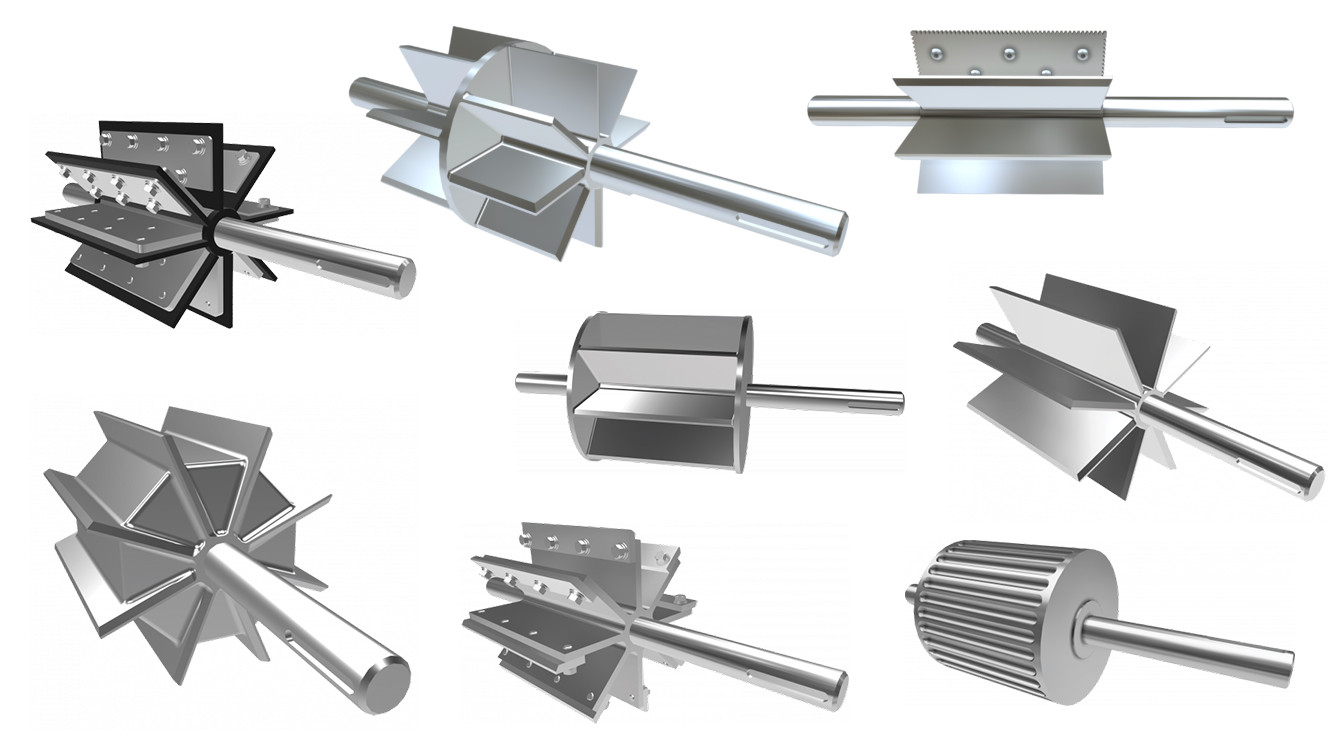

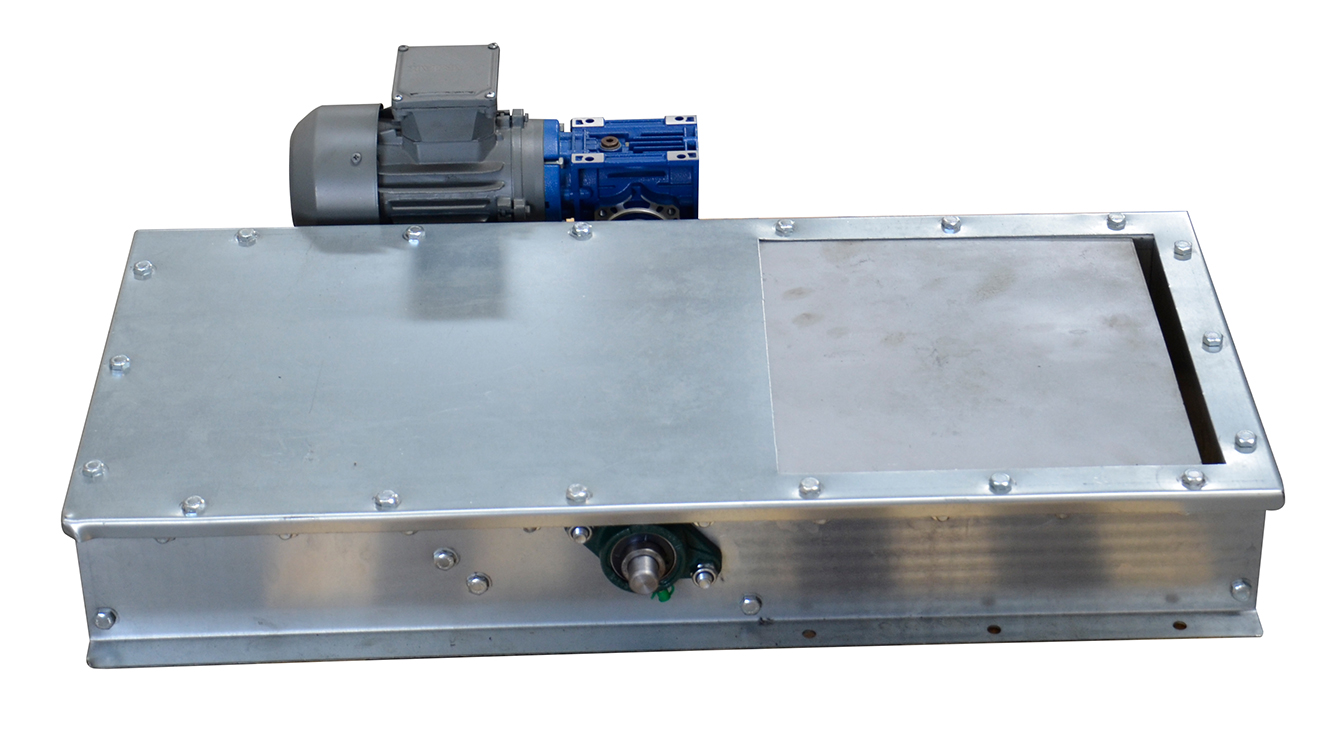

Makilus Big Bag unloading systems are designed to empty bulk bag materials automatically, safely, and efficiently. Depending on the product and application, various designs are available, including a modular steel platform, winch console, forklift console, four-way monorail crane, lifting hooks, and a bag seating frame. Vibrating or flap-type discharge units, a discharge hopper, and bag mouth locking devices ensure a controlled and dust-free unloading process.

Working Principle

The Big Bag is lifted by a monorail crane and placed onto the unloading platform. The tied mouth of the bag is secured in the locking device and released. The material is then transferred via screw conveyor or pneumatic conveying system to the required destination. During this process, vibration and dosing units can be activated for continuous and efficient discharge. For dusty materials, filter systems are added, while load-cell and control panel integrations allow real-time product monitoring. This ensures smooth transfer to multiple points, between floors, or across long distances.