Jet Pulse Filter

What is a Jet Pulse Filter?

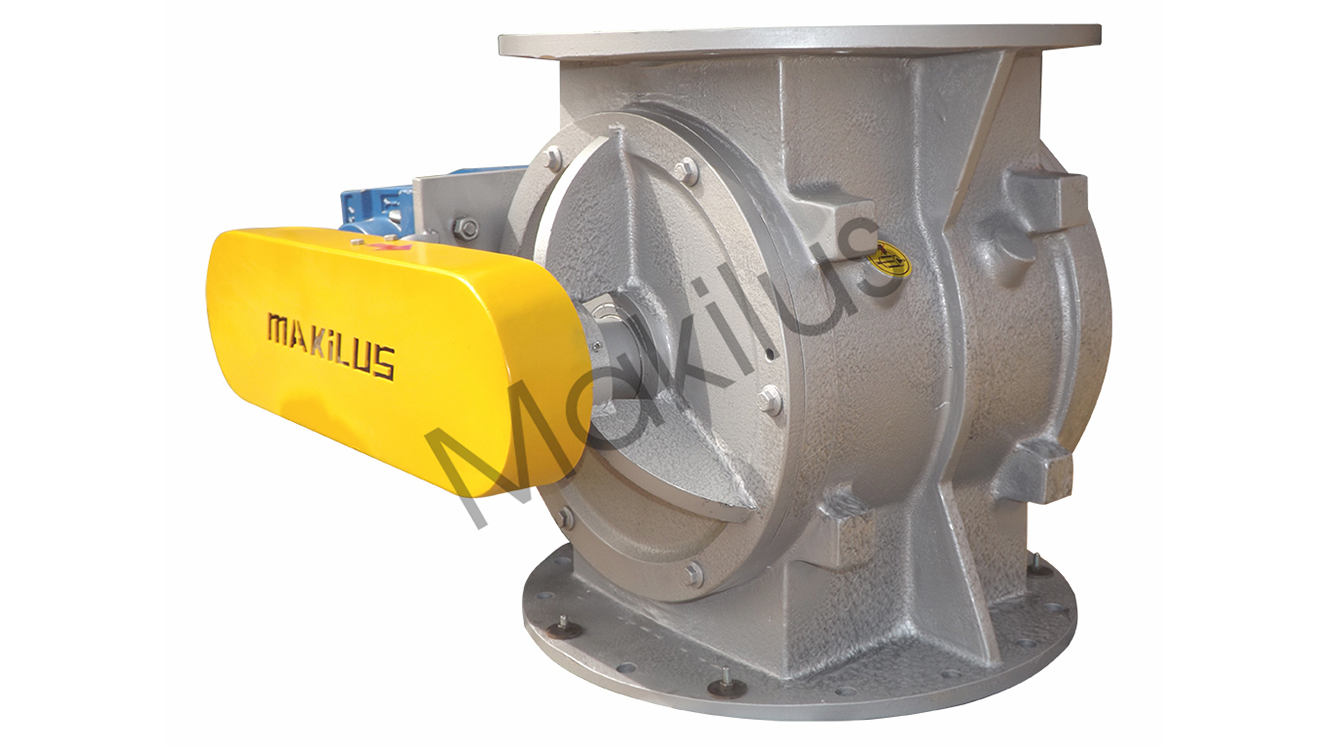

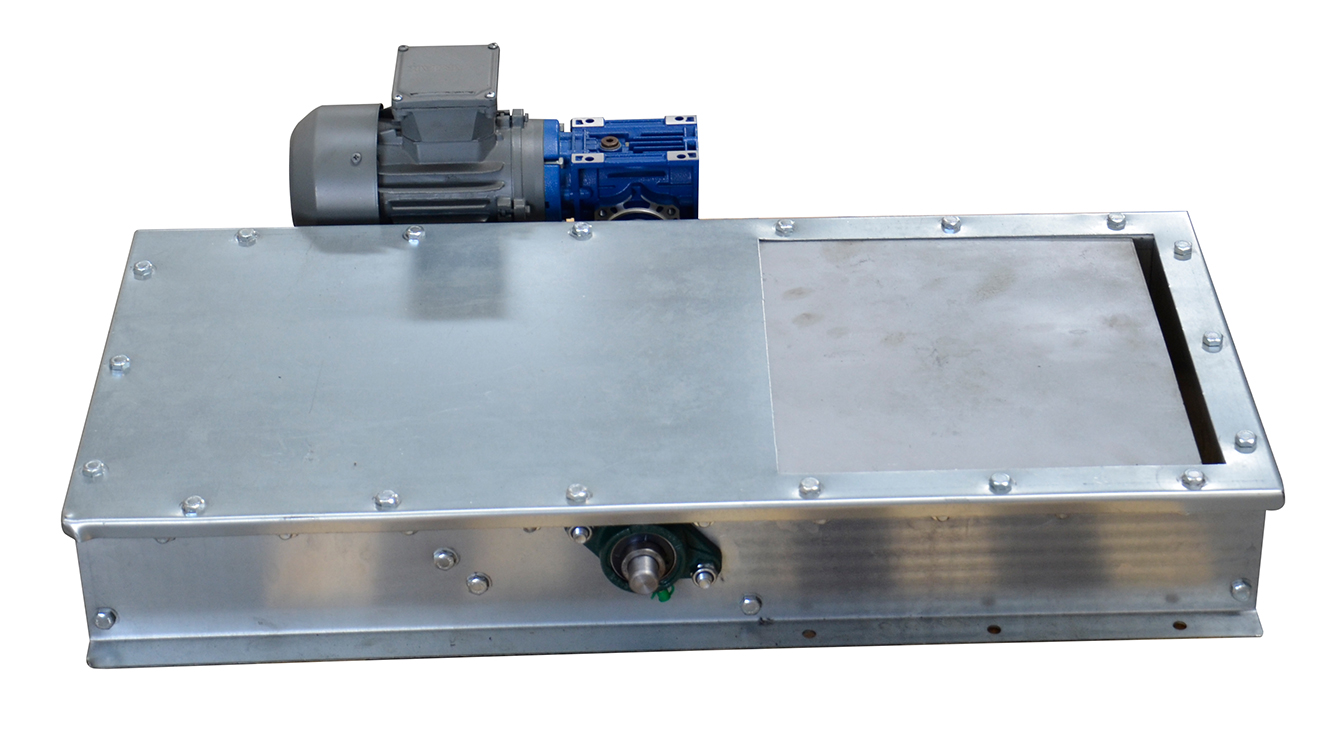

The Jet Pulse Filter is a high-efficiency filtration system designed to control dust and fume emissions in industrial environments. Widely used in steel, cement, food, and plastic industries, it operates in integration with pneumatic systems to ensure clean airflow in production areas. The filter size and type are selected based on the physical and chemical properties of the dust, ensuring both worker safety and increased machine efficiency.

Working Principle and Automatic Cleaning

Contaminated air enters the filter cabin from the side walls, where a deflector plate traps particles. Sparks, large or abrasive materials are directed into the airlock to extend filter life. Captured dust is automatically removed through the pulse-jet cleaning system. The cleaned air is then discharged back into the environment via a fan, ensuring continuous and safe filtration.

Advantages and Applications

Thanks to its compact design, the Jet Pulse Filter requires minimal installation space. Its modular structure reduces logistics costs and shortens installation times. Collected dust can be pneumatically transferred to a storage silo. The automatic cleaning system minimizes maintenance costs while extending filter life. With high filtration efficiency, it guarantees reliable and long-term performance in industrial operations.