Roto Flow

Product Description

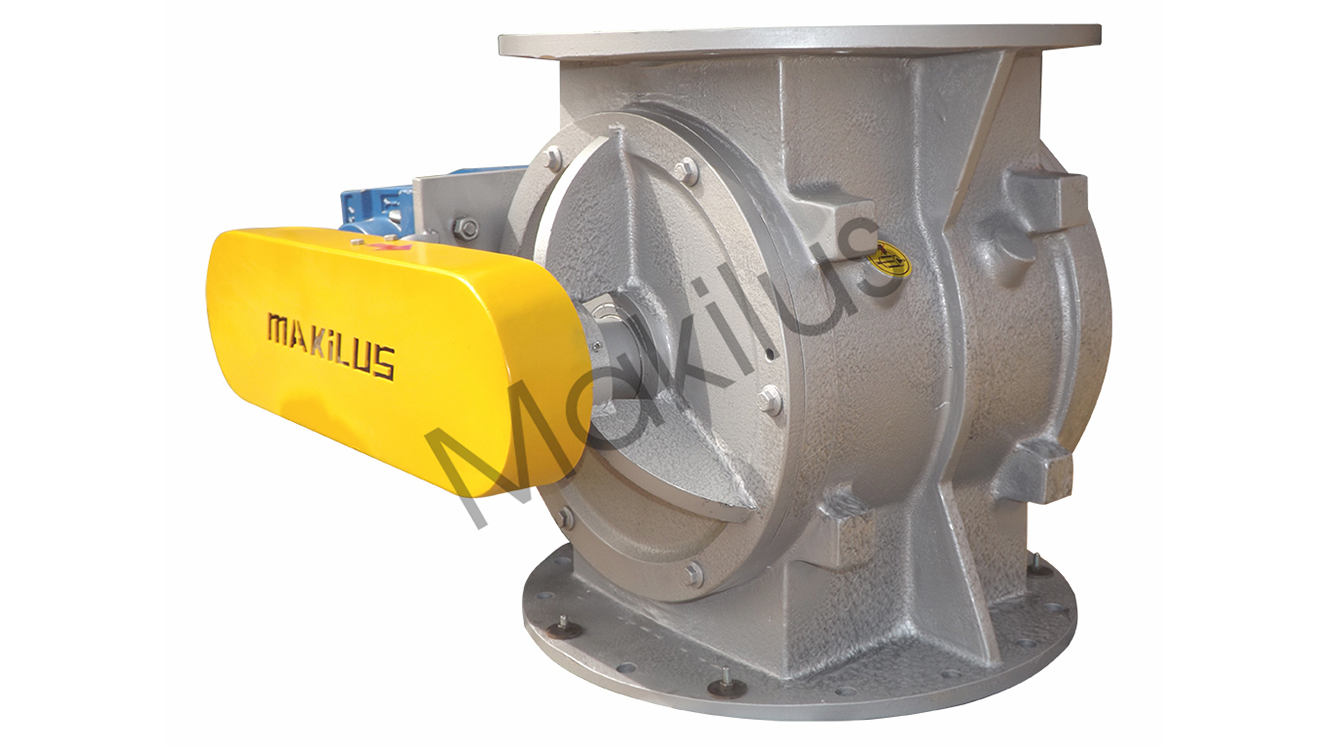

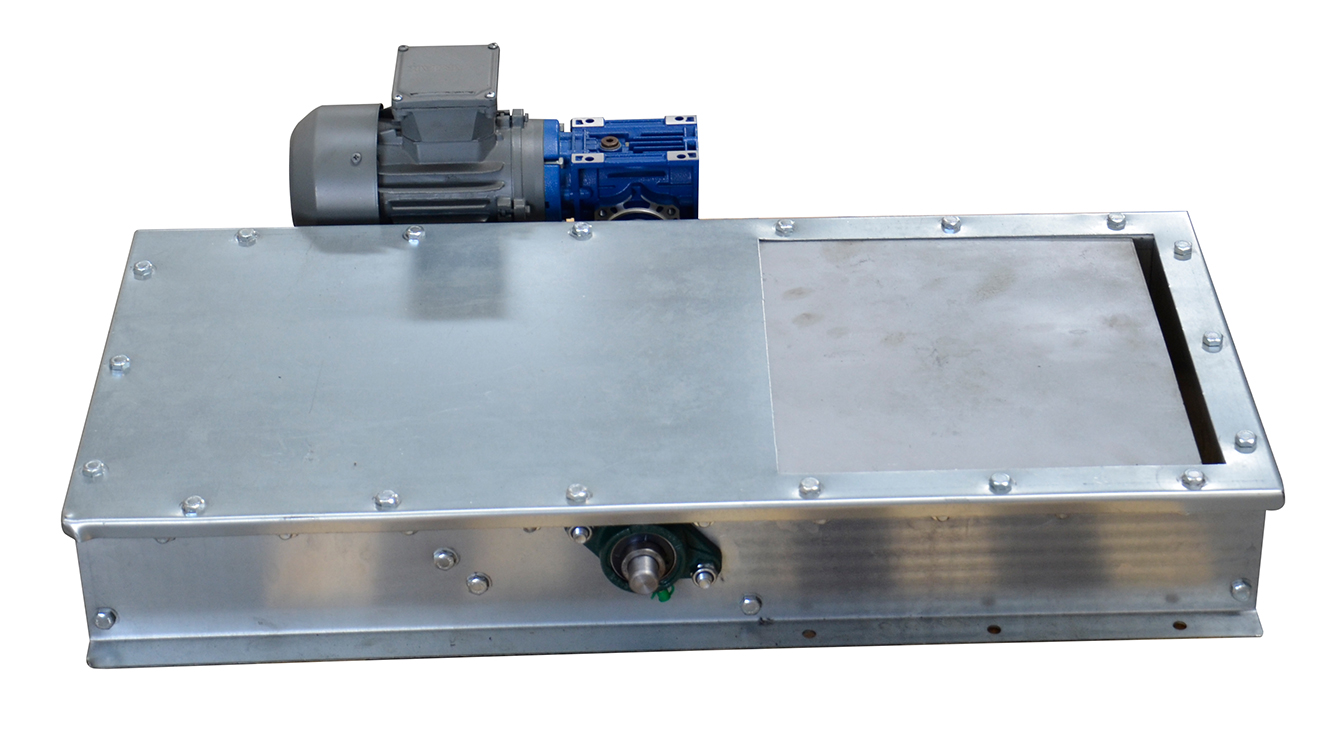

Makilus Roto Flow discharge systems are designed for safe, controlled, and efficient unloading of materials from silos and storage units. Thanks to its dual-hopper design, the material flow is stabilized, reducing the risk of blockages. The outer hopper is mounted to the bottom of the silo through a flange connection, ensuring secure and leak-proof installation. This system is ideal for powders, granules, and free-flowing bulk materials.

Working Principle

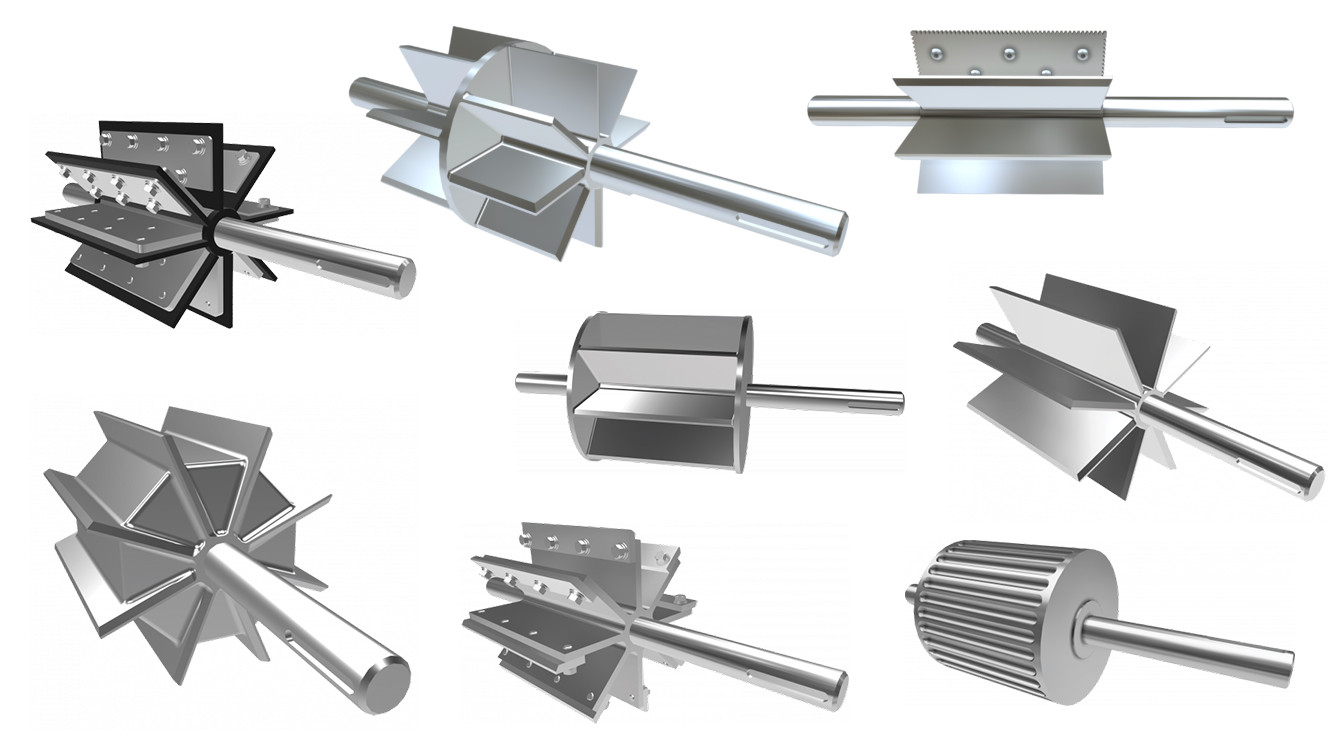

In the Roto Flow system, material is guided smoothly through the hoppers with the help of vibratory motion. The vibration mechanism prevents bridging and sticking, enabling continuous and uninterrupted discharge. The dual-hopper design ensures balanced flow and supports process continuity. It can be integrated with pneumatic conveying systems, screw conveyors, or other transfer equipment.

Advantages

-

Prevents material bridging and blockages.

-

Secure installation with leak-proof flange connection.

-

Dual-hopper design provides high-capacity continuous discharge.

-

Vibratory motion ensures efficient product flow with minimal loss.

-

Long service life with low maintenance requirements in industrial use.