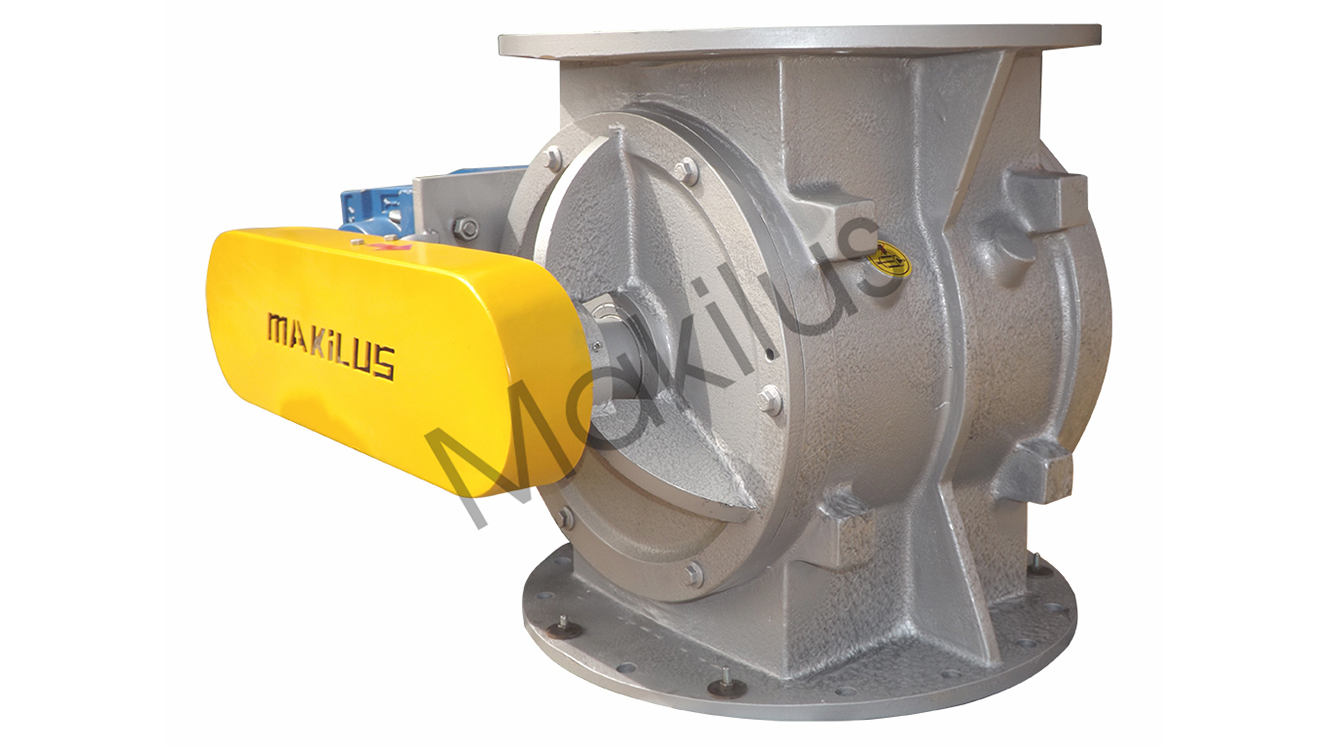

M Series Blower

Power and Design of M Series Blower

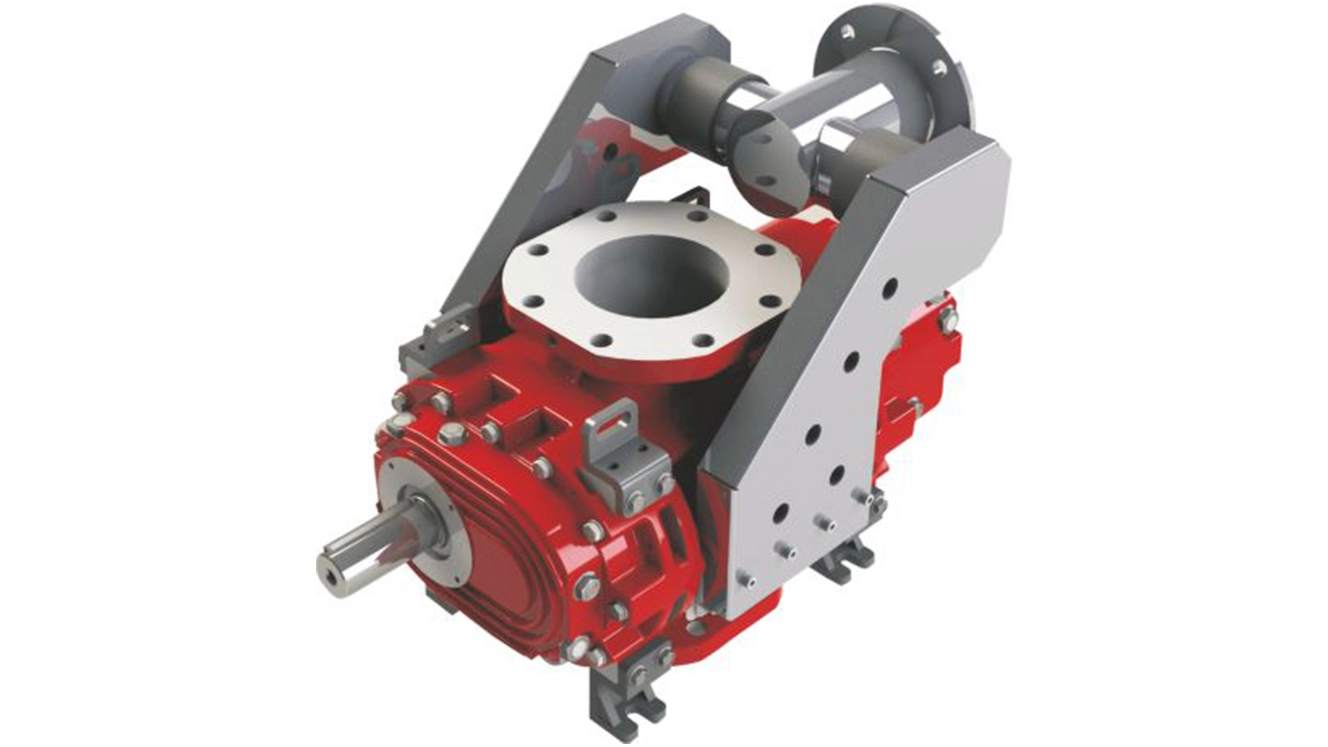

Makilus M Series Blower is designed with a positive displacement rotary system and three-lobe rotor structure, ensuring efficiency and durability. With its robust body and precision-engineered rotors, it provides stable and continuous operation in challenging industrial environments. The blower can perform both vacuum and pressure functions, offering flexibility to businesses. Its energy-efficient design, compact structure, and low maintenance requirements make it a cost-effective solution.

Wide Industrial Applications

The M Series Blower is widely used in pneumatic conveying systems, water treatment plants, sandblasting, bottling facilities, paper processing, aquaculture aeration, and packaging. It also plays a crucial role in ventilation, textile, mining, galvanizing, steel production, chemical processes, agriculture, tobacco processing, cooling, drying, and central dust collection systems. With such a wide application range, the M Series is an essential piece of equipment for industrial facilities.

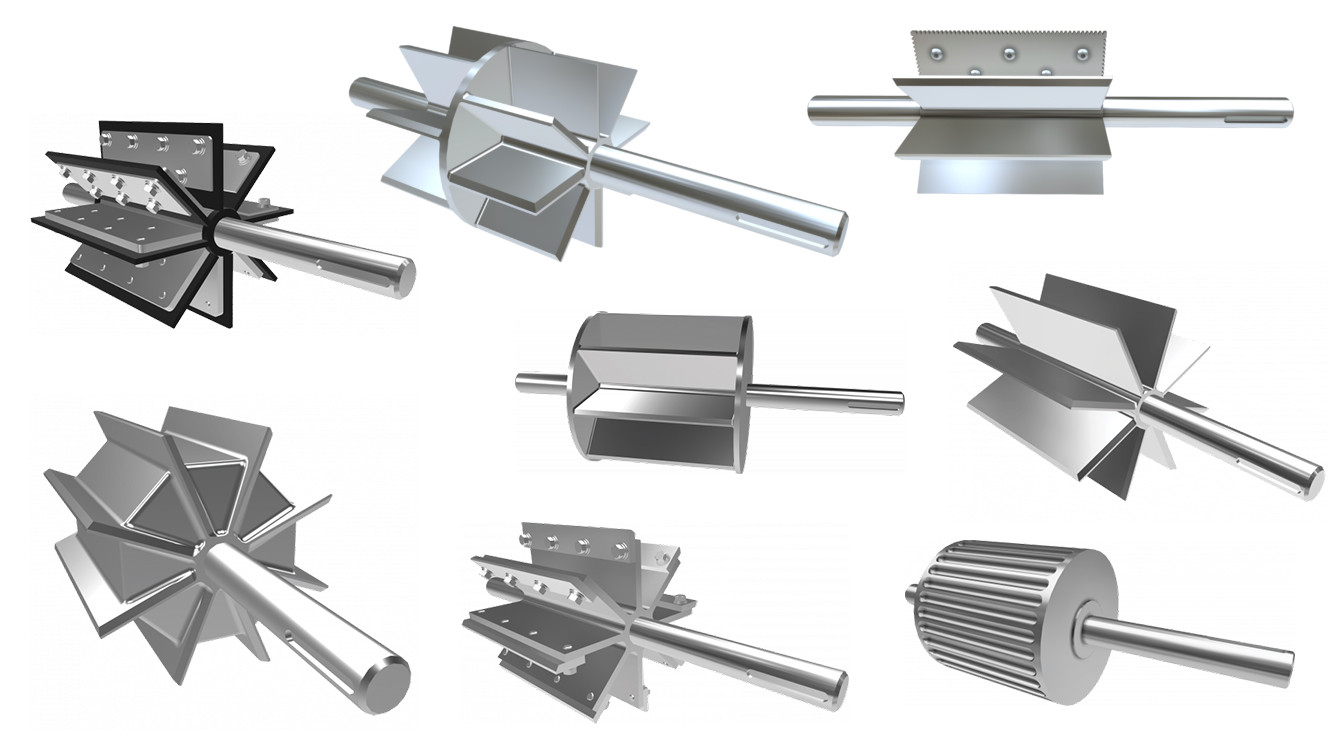

Safety, Equipment, and Components

Makilus M Series Blower is equipped with high-quality parts and safety features such as suction filter, pressure silencer, pressure relief valve, non-return valve, vibration dampers, motor tensioning, V-belt drive, and pulley guard. The robust housing and chassis ensure long-term durability, while the monitoring instruments allow operators to maintain stable and safe performance. With its advanced engineering, Makilus guarantees both safety and efficiency for long-term use.

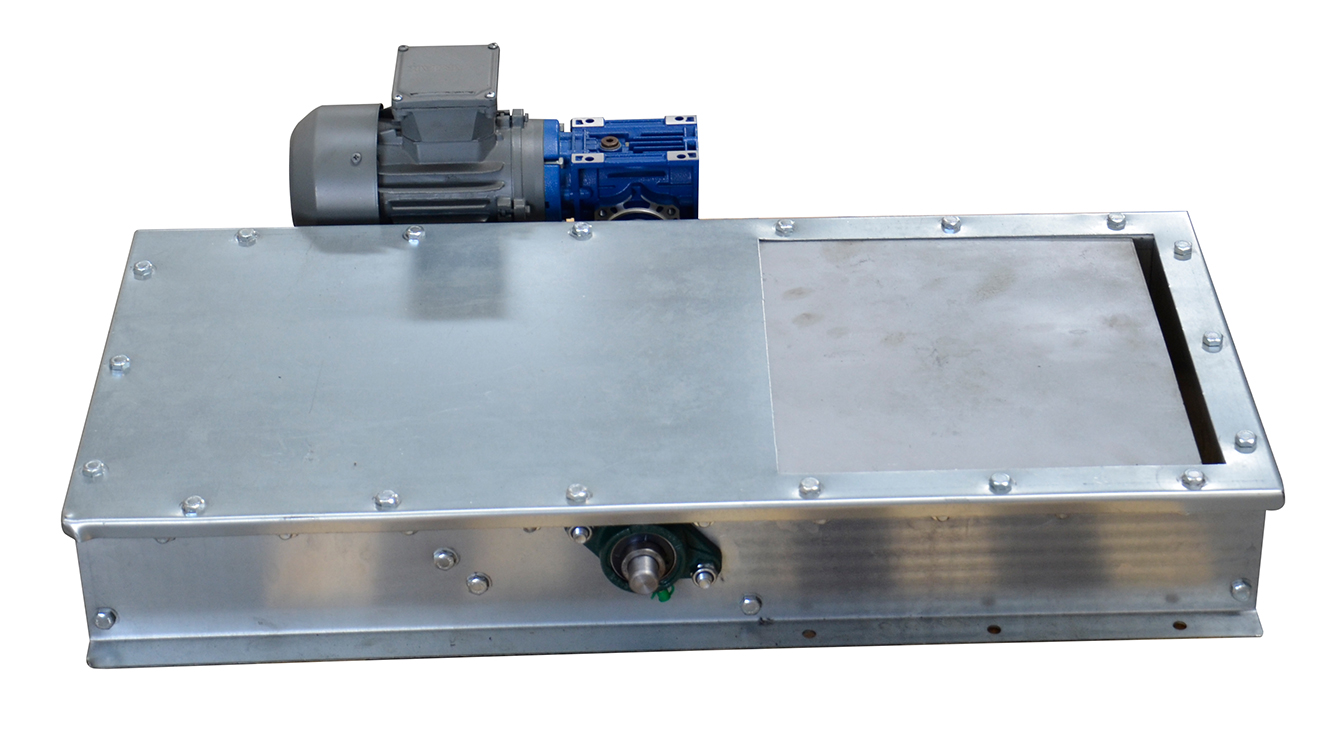

- Air blower main body

- Chassis

- Intake filter

- Pressure silencer

- Pressure relief valve

- Pressure gauge

- Check valve

- Anti-vibration mounts

- Engine tensioner

- V-belt drive

- Belt pulley guard