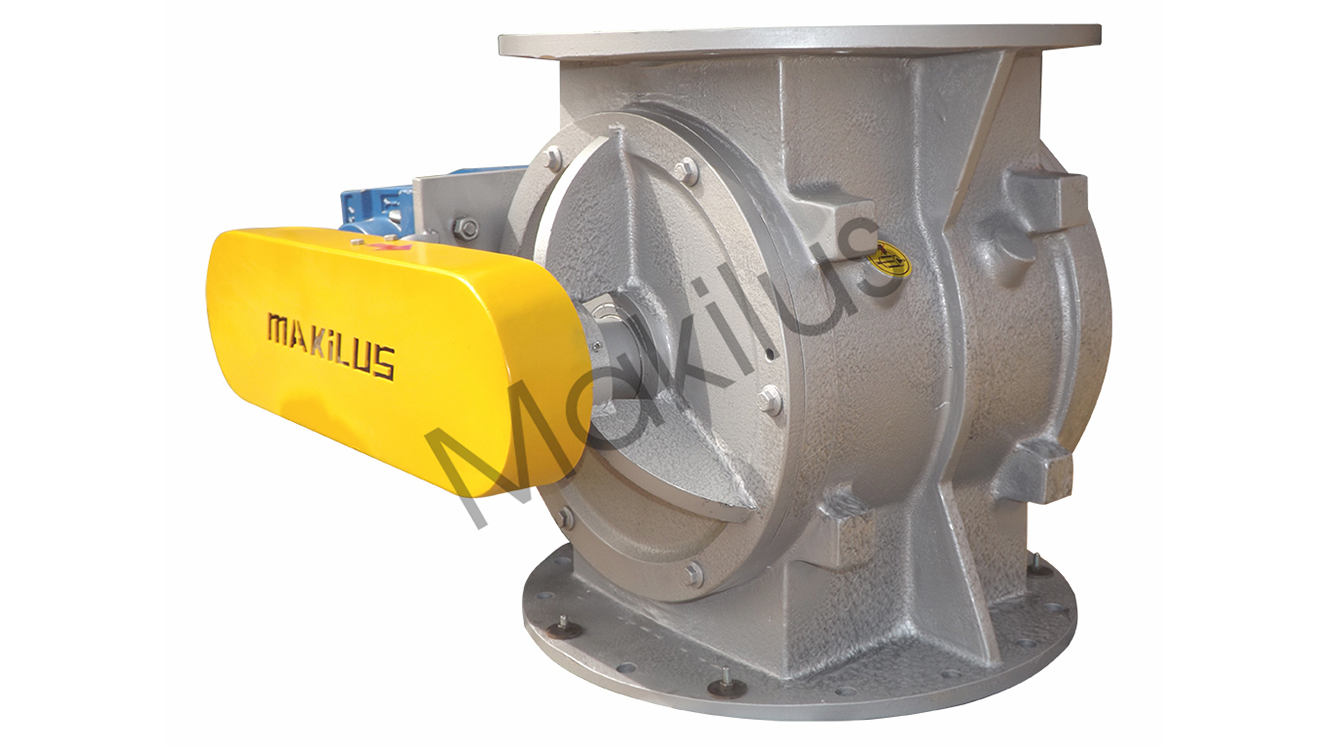

Q Series Blower

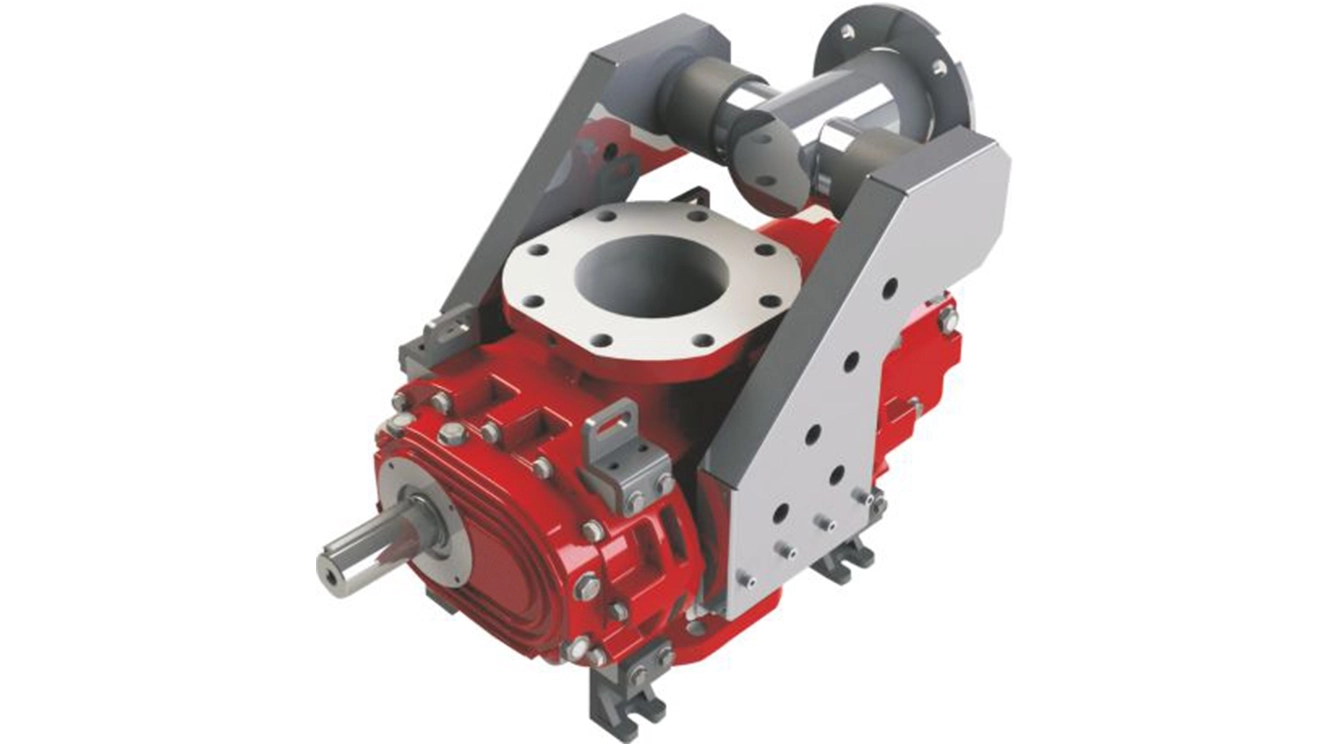

Power and Design of Q Series Blower

Makilus Q Series Blower is a positive displacement rotary type equipment developed to deliver maximum efficiency in industrial applications. Thanks to its three-lobe rotor design, it ensures low vibration, high performance, and long service life. By transferring the movement from the motor to the rotors, it performs both vacuum and pressure functions in a single unit. This makes the Q Series an ideal solution for processes that require high-capacity air transfer. With its durable body, energy-saving structure, and easy maintenance features, the Q Series Blower guarantees reliable and economical operation for demanding industries.

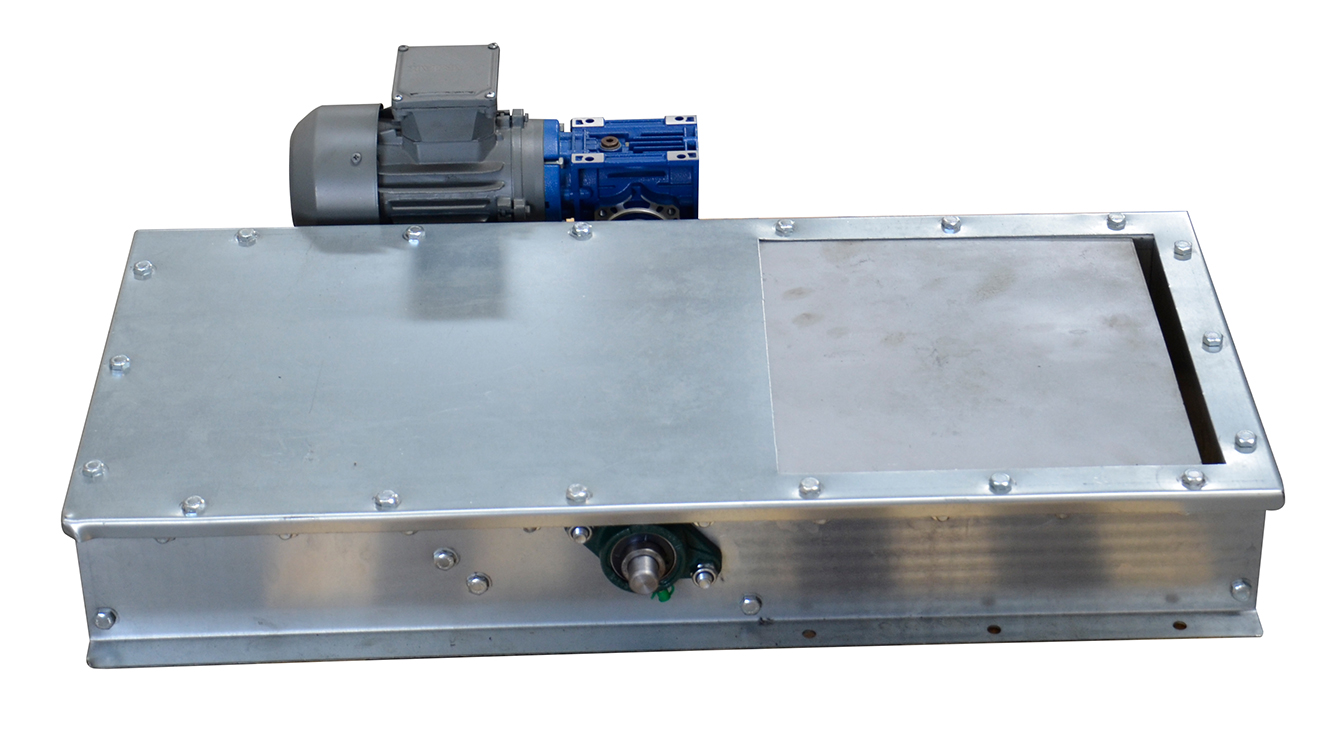

Wide Range of Applications

Q Series Blowers are used across multiple industries with great efficiency. They play a key role in pneumatic conveying systems, wastewater treatment plants, sandblasting systems, bottling facilities, paper processing industries, aquaculture aeration, and packaging processes. They are also widely preferred in ventilation, dust collection, mining, textile, chemical, steel, agriculture, and cooling technologies. With its versatile structure, the Q Series provides businesses with reliable and flexible solutions in diverse applications.

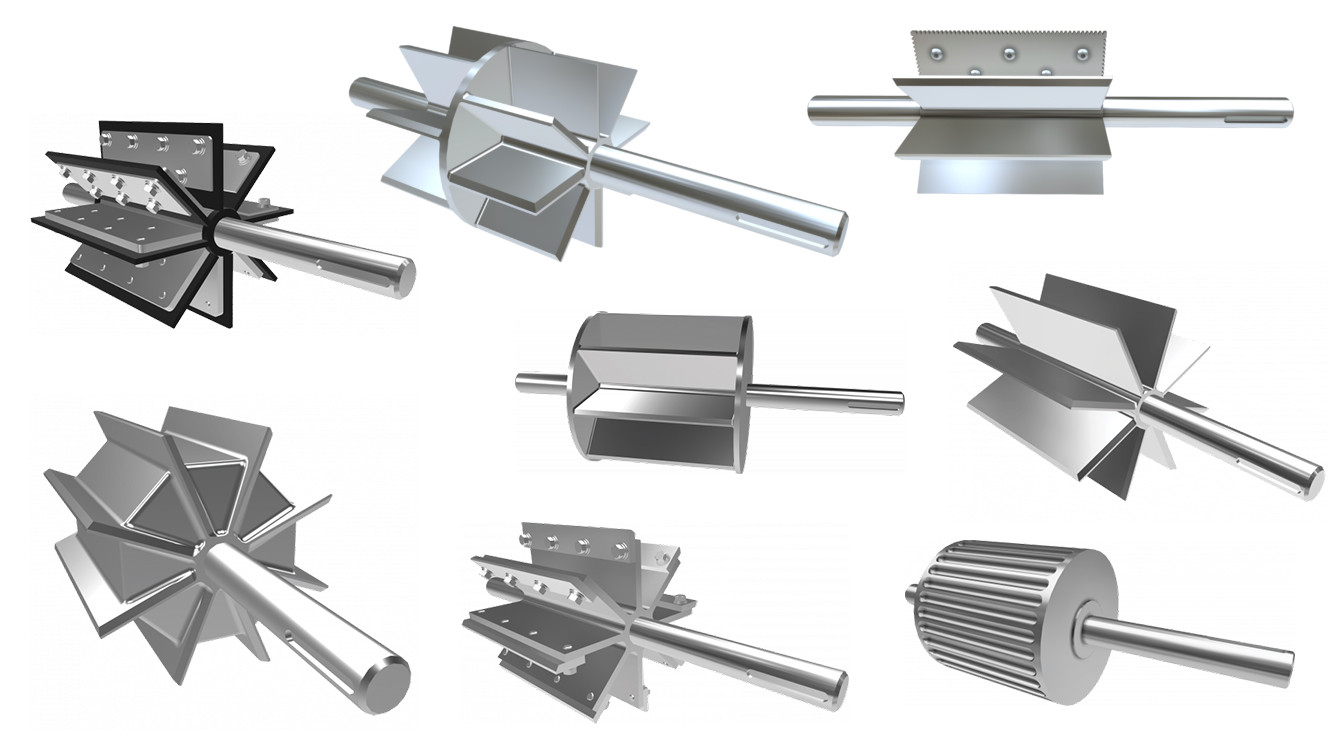

Safety, Equipment, and Components

Makilus Q Series Blower is equipped with multiple safety and operational features. Standard equipment includes suction filter, pressure silencer, pressure relief valve, non-return valve, vibration isolators, and pressure gauge. The V-belt drive system and motor tensioning mechanism ensure stable operation, while the pulley guard provides additional workplace safety. These robust components, designed with Makilus engineering expertise, offer durability, efficiency, and a long operational lifespan.

Parts List

- Air blower main body

- Chassis

- Intake filter

- Pressure silencer

- Pressure relief valve

- Pressure gauge

- Check valve

- Anti-vibration mounts

- Engine tensioner

- V-belt drive

- Belt pulley guard